wendy@baogemachine.com

-

-

-

China Manufacturing Factory

wendy@baogemachine.com

China Manufacturing Factory

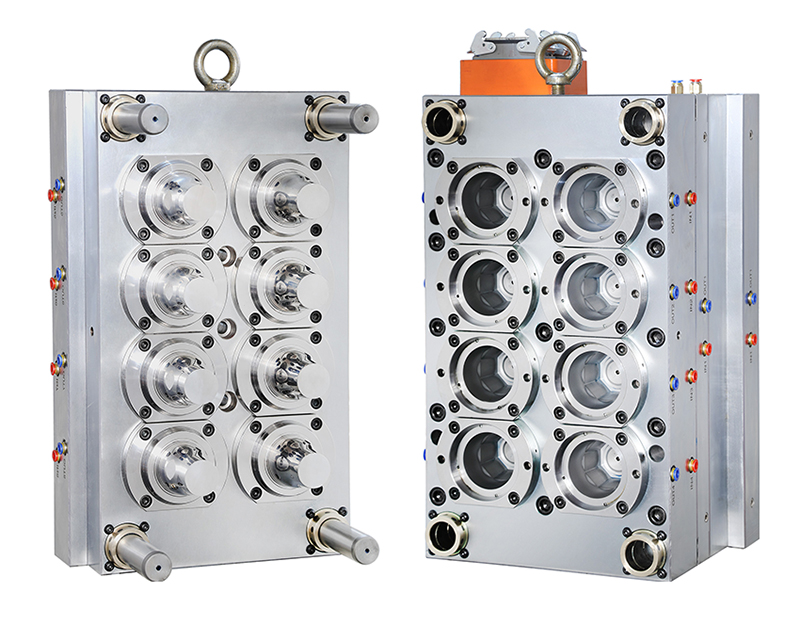

1.We are one of the most reliable companies in this domain offering PET Preform Mould with advanced mould design technology.

Multicavity: 1-8 cavity, 12 cavity, 16 cavity, 24 cavity, 32 cavity, 48 cavity, 56 cavity, 72 cavity and 96 cavity.

Neck finish:PCO, 1810,1881,30/25,29/25,38 ,ALASK, ROPP; Jar neck and others.

COOLING SYSTEM

spiral water cooling way on cavity enhances mold cooling.

cooling system on neck and move neck plates brings an enhance cooling.

precise distributary plate distributes cooling water into cavity evenly,quicken preform cooling.

HOT RUNNER

hot runner balance design ensures evenly force,uniform heating and identical preform.

less energy cost and pressure lost.

independent cavity control system ensures nozzle temperature fluctuates within 1 .Adopt imported heating devices,Germany Hotset or Italy Rotfil.

Mold Name: Pet Preform Mold

Plastic Material: PET

Mold base steel: P20

Core Cavity Steel: S136

Cavity Quantity: Multi

Runner Type: Hot Runner

Gate Type: Valve Gate

Injection type: Drop Automatic

A: Mould Design

12 Cavities Jar Edible Oil Bottle Pet Preform Injection Molds

Good pet preform mould design is the first step,PRC mould has 3 designers with more than 15 years experience.

1:We will analyze the feasibility,shrinkage and molding temperature of plastic products.

2

:We will communicate with customers,including details such as

weight,style design,size and appearance,stability and wear resistance of

plastic products.

3:Design and mold flow analysis are provided free of charge.

B: Mould Metal Material

Choose different steel according to plastic product material,mould life and customers requirements.

We all buy mould raw material from large metal companies.

We personally test the hardness of the mould steel.

There are strict inspection procedures for the hardness of mould steel,and mould life is 1000000 to 3 million shots.