wendy@baogemachine.com

-

-

-

China Manufacturing Factory

wendy@baogemachine.com

China Manufacturing Factory

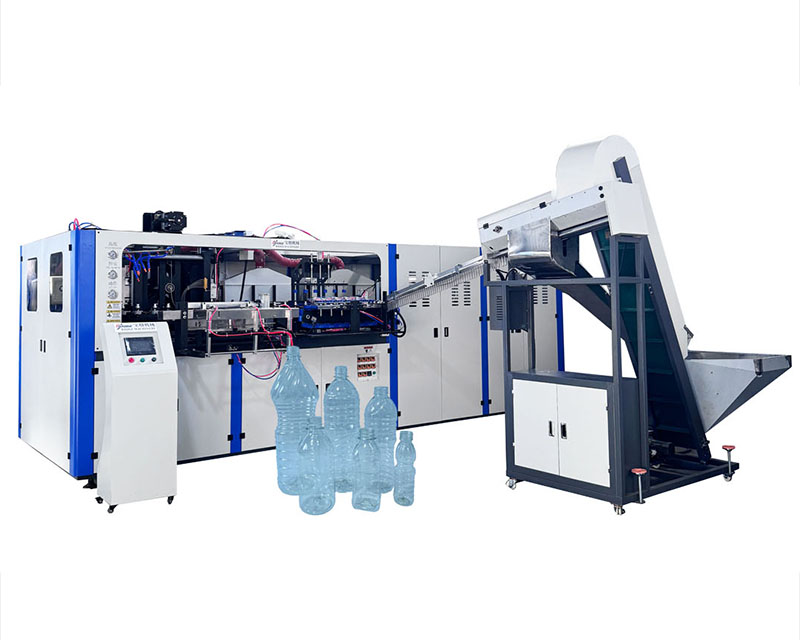

PET Bottle Blowing Machine,Plastic Bottle Molding Machinery

SAVE ENERGY :The preform heating and blowing are on separated section, so that it can save the waiting time of each unit. Thepreforms are heated intensively, as the rotary machine heating type, improve the heating eficiency. Meanwhile, the high pressure air cansaved by air recycling system, for the pre-blow or low pressure air supply, save energy.

SAVE SPACE: The infeeding system is inside the machine, the heating structure save the preform pitch distance, save the space

HIGH EFFICIENCY: We improve about 20% output, in the situation of low down the machine energy

INFEEDING SYSTEM: The infeeding system is in single channel with less sensors for better infeeding.

HEATING SYSTEM: Preforms are heated intensively, the cooling device and the cross ventilation protect the preform neck from out ot shape, improve the energy utilization, and heating efficiency

TRANSFER UNIT: The variable pitch device is controlled by servo for stable and accurate transferring

CLAMPING UNIT: The clamping unit is controlled by servo motor to ensure the synchronization, stable running and precise location

HIGH PRESSURE AIR RECYCLE SYSTEM: The high pressure air recycle system save the high pressure to the tank, reduce the noiseand save energy lost.