wendy@baogemachine.com

-

-

-

China Manufacturing Factory

wendy@baogemachine.com

China Manufacturing Factory

Our company have strong technology strength,completely equipment.we hold advancedmechanical equipment,such as CAD/CAM/CAE computer system,And TaiWan high speednumerical control punch, High speed numerical lathe(6000/min),Japan electric light slowsilk thread cutting etc high precision equipment, have ensured the consistent quality ofhigh-precision moulds.

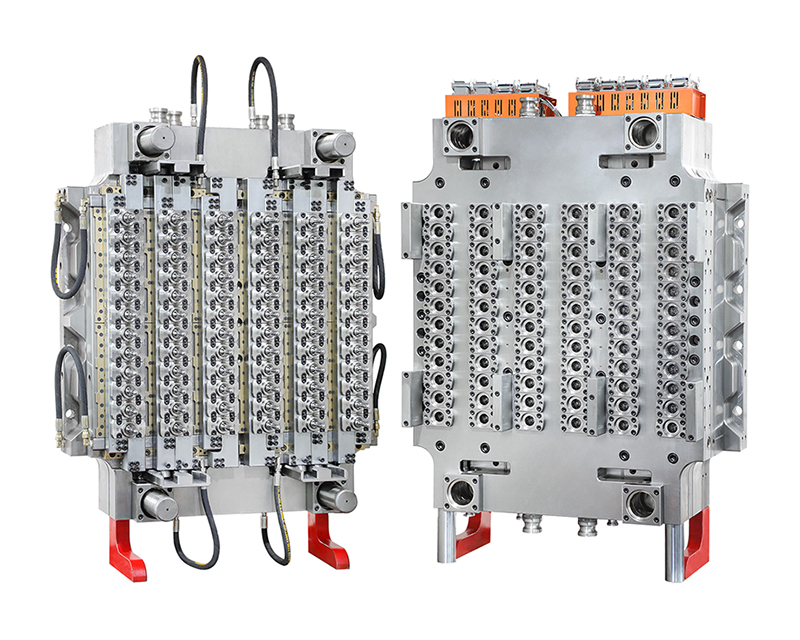

| Mold Model | 72 cavity Pet preform water mould |

| Preform Neck | 28mm / 30mm |

| Preform Weight | 13g / 15g..... |

| Runner | Hot runner |

| Core Material | S136 |

| Cavtiy Material | S136 |

| Screw Neck Material | S136 |

| Mold Base | 4CR13 Steel/P20 |

| Cycle time | 16s |

| Mold Life | 5millions |

| Scope of Application | water bottle |

| Delivery time | 60-70days |