wendy@baogemachine.com

-

-

-

China Manufacturing Factory

wendy@baogemachine.com

China Manufacturing Factory

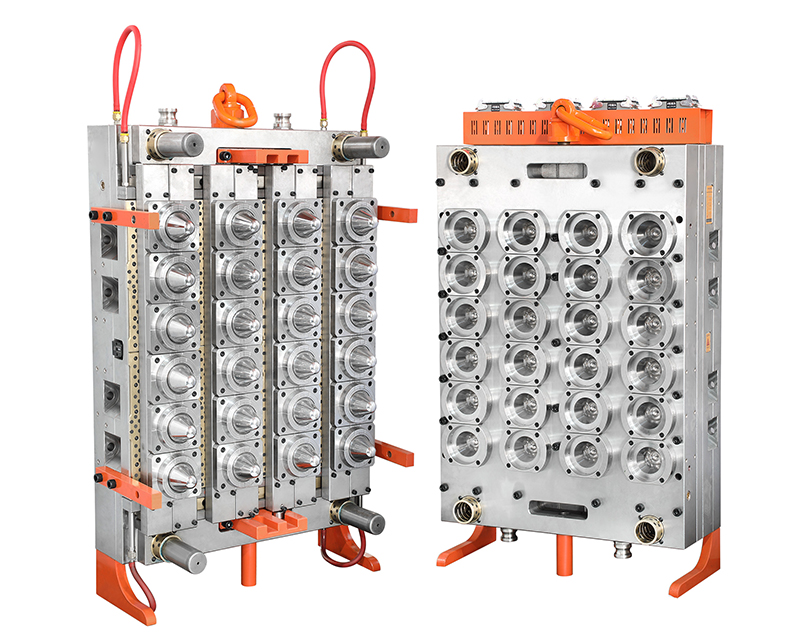

Salient features of our molds are: Optimised Preform design of molds to ensure dynamic results in bottle blowing Preform molds with valve gate Hot Runner system Manufactured in modular concept for standard interchangeable mold components for ease of replacement. Variation in Preform wall thickness of ±0.10mm, depending on its length Machining tolerances of the order of 0.005mm (5 microns) A well-balanced cooling channel layout and turbulent water flow for consistency in cooling and efficient heat transfer Application of internationally advanced two-step dual taper locating technology Independent self-locking of each cavity to ensure high concentricity of product

Mold Name |

Jar Preform Mould |

Raw Material |

PET, PP |

Cavity No. |

4, 6, 8, 12, 16, 24, 32, 48, 64, 72, 96, etc. |

Injection Gate |

Hot Runner Valve Gate |

Guarantee Time |

5 Million Shots |

Eject way |

Eject Plate or Robot |

Core&Cavity |

S136 (HRC46-48) |

Mold Base |

P20 |

Delivery Time |

60 Working Days |

Mold Feature |

With Interchangeable Insert and Integral Cooling Channel |

| Product Name | Jar preform mould |

| Core &Cavity Steel | 2316#steel, S136 stainless steel or based on customer's requirement. |

| Mould base & Standard Component | DME,HASCO,MISUMI,LKM,Self-made with P20, 3CR13, 4CR13 material etc. |

| Steel hardness: | HRC30-35 for base material. |

| HRC45-48 for core and cavity material. | |

| HRC60-62 for special parts material | |

| Plastic material | PET, PP, etc. |

| Cavity Number | 1*4, 1*6, 1*8, 1*12, 1*16, 1*24, 1*32, 1*48 etc |

| Injection System | Pneumatic Valve gate with shut off&free-cut or short tail or long tail etc |

| Ejector System | Mould slider + Stripper plate ejection |

| Cycle Time | Based on PET preform thickness |

| Tooling lead time | 30-60 Days |

| Mould life | At least 2.0million Shots |

| Quality assurance | CE certificate for European customers |